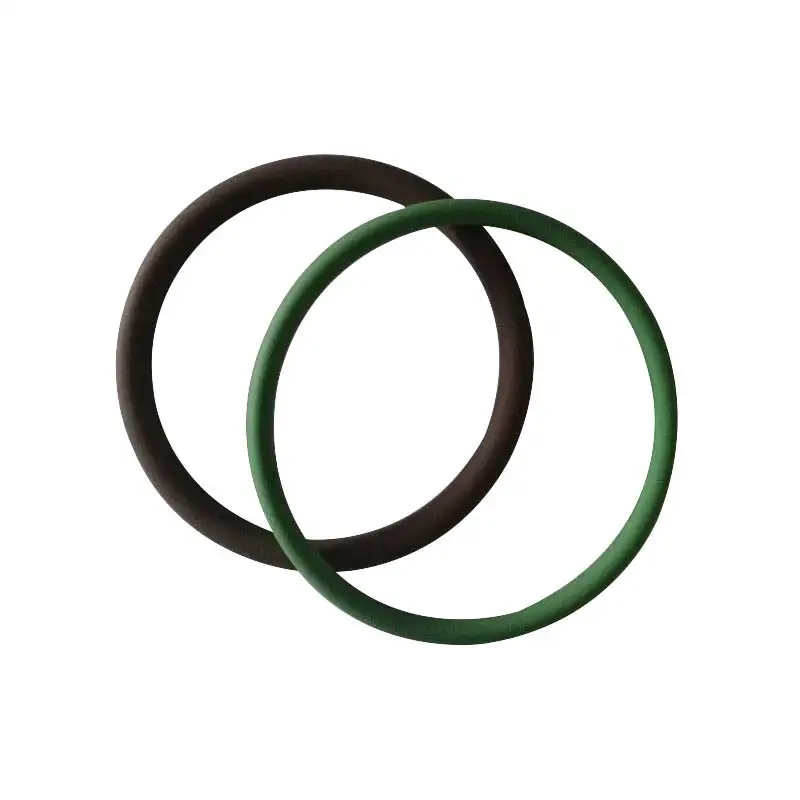

Polishing Viton o-ring

O-Ring Technical requirements

Appearance meets GB/T3452.2-2007 Material meets HG/T2579-2008 Size meets GB/T3452.1-2005

In addition , all our products are ROHS and REACH Compliant (we mainly export products to USA and Europe market).

ADVANTAGES

The company introduced the international quality system- ISO 9001-2000 to guide the production and operation.

O-Ring ADVANTAGES 01

O-Rings offer an efficient and economical sealing element for a wide range of static or dynamic applications.

O-Ring ADVANTAGES 02

2.O-Ring sizes are defined by the inner diameter-ID and the cross section-CS , our o-ring Inner Diameter can be from 0.5mm to 1500mm .

O-Ring ADVANTAGES 03

Standard sizes such as AS568(PARKER sizes), JIS(P TYPE,G TYPE,S TYPE ,V TYPE ,F TYPE sizes) BS1516 sizes Metric sizes as well as non-standard sizes are all available.

O-Ring ADVANTAGES 04

We have more than 5000 o-ring mould , so you could get any size here without set-up or tooling charge . Huge inventory of o-rings can meet your urgent requirements.

O-Ring ADVANTAGES 05

A very wide range of rubber material can be selected , main material: NBR (BUNA-N, Nitrile) , VITON(FKM) , Silicone(VMQ) HNBR, FFKM ,EPDM , PU(Polyurethane , urethane),Fluorine silica gel(FVMQ),Neoprene(CR) and so on. Hardness of material can be from 40 Shore-A (hardness) to 90 Shore-A (hardness)

O-Ring Features 06

Good sealing solution , long service life .

Easy installation reduces risk .

Working in various medium based on different elastomer material.

PARAMETER

There are two modern production workshops and a series of advanced production and testing equipment.

Material:FKM

Color:Customized according to Pantone colors

Hardness:50-90 shore A

Size:Customized

Manufacture method:Mould pressing

Temperature:-20~+200°C

Certificate:SGS, Rosh

Package:Plastic bags/Carton boxes

Lead time:

1) 1-2 days if goods in stock

2) 10-15days if goods out of stock with molding

3) 15-20 days if goods out of stock without molding

4) Store, Prompt shipment if annual requirement informed

Port of Loading:Shanghai

Delivery Ways:By air/sea/train/express

Drawings:2D or 3D

DETAILS

Our products are sold not only the domestic many areas,but also exported to United states,Brazil,Italy,Sweden,Germany and other countries.

| O-ring Relation Between Hardness and Pressure | |||||

| Shore A Hardness | (IRHD) Hardness | Using scope | |||

| 40+/-5 | Seal in low pressure | ||||

| 50+/-5 | |||||

| 60+/-5 | 63+/-5 | ||||

| 70+/-5 | 73+/-5 | Seal in common conditons | |||

| 80+/-5 | 83+/-5 | Seal in high pressure | |||

| 90+/-5 | 93+/-5 | ||||

| shore A | 35KG/c㎡ | 70KG/c㎡ | 105KG/c㎡ | 140KG/c㎡ | 175KG/c㎡ | 210KG/c㎡ | 350KG/c㎡ | |

| 1.78 | 70 | 0.15 | 0.1 | 0.05 | ||||

| 80 | 0.2 | 0.15 | 0.1 | 0.05 | 0.03 | |||

| 90 | 0.25 | 0.2 | 0.13 | 0.1 | 0.08 | 0.05 | 0.03 | |

| 2.62 | 70 | 0.18 | 0.13 | 0.08 | ||||

| 80 | 0.25 | 0.18 | 0.13 | 0.08 | 0.04 | |||

| 90 | 0.3 | 0.25 | 0.18 | 0.13 | 0.1 | 0.08 | 0.04 | |

| 3.53 | 70 | 0.2 | 0.15 | 0.1 | ||||

| 80 | 0.3 | 0.2 | 0.15 | 0.1 | 0.05 | |||

| 90 | 0.4 | 0.3 | 0.2 | 0.15 | 0.13 | 0.1 | 0.05 | |

| 5.34 | 70 | 0.25 | 0.18 | 0.13 | ||||

| 80 | 0.35 | 0.25 | 0.18 | 0.13 | 0.06 | |||

| 90 | 0.45 | 0.35 | 0.25 | 0.18 | 0.15 | 0.13 | 0.06 | |

| 7 | 70 | 0.3 | 0.2 | 0.15 | ||||

| 80 | 0.4 | 0.3 | 0.2 | 0.15 | 0.07 | |||

| 90 | 0.5 | 0.4 | 0.3 | 0.2 | 0.18 | 0.15 | 0.07 |

| ID | Tolerance(+/-) | W | Tolerance(+/-) |

| 4 - 14 | 0.13 | 0 - 1.68 | 0.15 |

| 14.01 - 15.6 | 0.18 | 1.69 - 2.51 | 0.15 |

| 15.61 - 25.12 | 0.23 | 2.52 - 3.4 | 0.15 |

| 25.13 - 29.78 | 0.25 | 3.41 - 5.16 | 0.15 |

| 29.79 - 34.65 | 0.28 | 5.17 - 6.73 | 0.15 |

| 34.66 - 44.17 | 0.33 | 6.74 -... | 0.2 |

| 44.18 - 50.52 | 0.38 | ||

| 50.53 - 66.4 | 0.46 | ||

| 66.41 - 75.92 | 0.51 | ||

| 75.93 - 94.97 | 0.61 | ||

| 94.98 - 107.67 | 0.69 | H | Tolerance(+/-) |

| 107.68 - 126.72 | 0.76 | 0 - 1.68 | 0.08 |

| 126.73 - 133.07 | 0.89 | 1.69 - 2.51 | 0.1 |

| 133.08 - 158.42 | 0.94 | 2.52 - 3.4 | 0.1 |

| 158.43 - 183.82 | 1.02 | 3.41 - 5.16 | 0.1 |

| 183.83 - 209.22 | 1.14 | 5.17 - 6.73 | 0.1 |

| 209.23 - 234.62 | 1.27 | 6.74 -... | 0.15 |

| 234.63 - 278.99 | 1.4 | ||

| 279 - 405.26 | 1.65 | ||

| 405.27 - 430.66 | 1.91 | ||

| 430.67 - 456.07 | 2.03 | ||

| 456.08 -... | 0.50% |

Leave a message

If you contact us now for more details, you can take samples for free. Our service team will get back to you within 24 hours normally!

Quick links

Products

Contact us

Tel: +86-13338652764

Company Tel: +86-0512-65792190