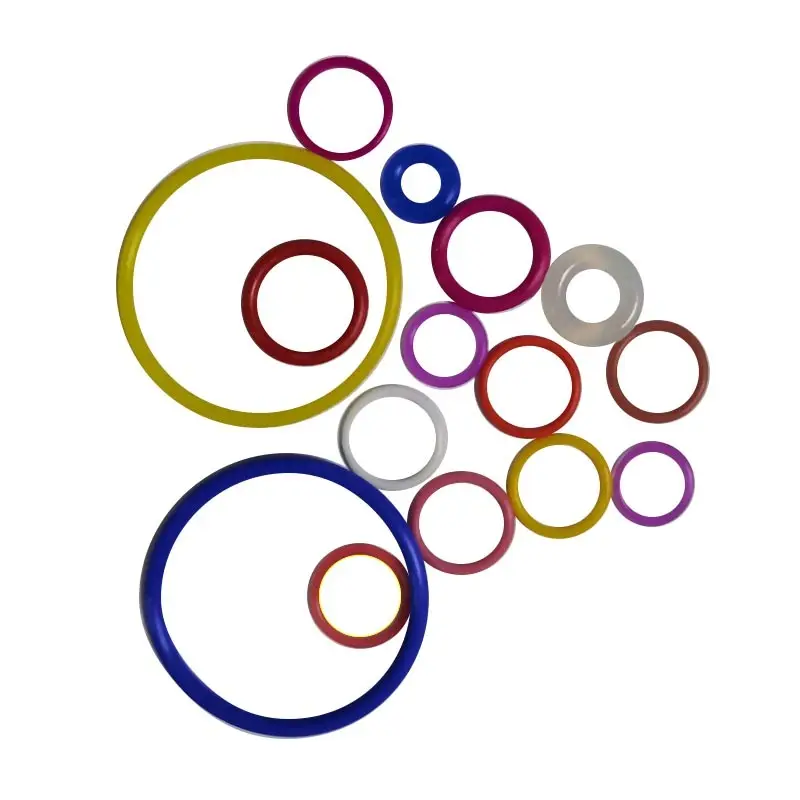

food grade rubber o ring seals personalized for automotive

Payment:

Prepaid

Delivery time:

10-15days

Start Port:

Shanghai

Size:

Customized

Color:

Customized according to Pantone colors

Package:

Plastic bags/Carton boxes

Delivery Ways:

By air/sea/train/express

Certification:

SGS, Rosh

rubber o ring seals

description

The tight weaving of the microfibers does cause any liquid to form beads on the surface of the fabric and stay for a short time, rather than soaking immediately.

rubber o ring seals

SPECIFICATIONS

| Payment | Prepaid |

|---|---|

| Delivery time | 10-15days |

| Start Port | Shanghai |

| Size | Customized |

| Color | Customized according to Pantone colors |

| Package | Plastic bags/Carton boxes |

| Delivery Ways | By air/sea/train/express |

| Certification | SGS, Rosh |

Suggested Videos

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data

Quick links

Products

Contact us

Contact Person: Mr.Huang

Tel: +86-13338652764

Company Tel: +86-0512-65792190

Tel: +86-13338652764

Company Tel: +86-0512-65792190

Office Add: Suzhou Industrial Park Zhongxin Ecological Building

Copyright © 2026 Suzhou Ultimate Sealing Technology Co.,Ltd. | Sitemap | Privacy Policy